Your Go-To Guide for Tools & Equipment for Successful Rock Breaking Projects

Hello Rock Breaking Enthusiasts!

Breaking through bedrock and tackling boulders might sound like a Herculean task, but fear not! Today, we’re unveiling the go-to tools and needed equipment for successful rock demolition for the average contractor. So, grab your hard hat, and let’s dive in!

Rock Breaking Tools: The Heavy Hitters

Before you break it, understand it! Remember that different rock-breaking projects will require different strategies depending on type, size and density of your rock. For example, bedrock usually demands endurance and a slightly different toolset and product line than the finesse of splitting and demoing boulders. With that in mind, here are our most used tools and equipment for your average rock-breaking project:

Standard Drill:

Your friend in making holes and creating a drill pattern that will be the foundation to your rock-breaking project’s success!

Overview:

A standard drill, often pneumatic or electric, is a versatile tool used for drilling holes into rock surfaces. It’s a foundational tool in many construction and rock-breaking applications.

Use in Rock Breaking:

Step in the Process: Drilling is often one of the first steps in the rock-breaking process. It creates holes for the insertion of expanding grout, piston splitters, or for initiating fractures with hydraulic breakers.

Applications: Drills are essential for creating precise holes in the rock to facilitate various breaking techniques.

Hydraulic Breaker:

The unsung heroes of rock breaking. These bad boys use hydraulic power to deliver percussive blows, making quick work of bedrock and boulders alike.

Overview:

A hydraulic breaker is a powerful attachment that mounts on heavy machinery, typically excavators. It operates on hydraulic power, delivering intense percussive blows to break through hard surfaces, such as rocks and concrete.

Use in Rock Breaking:

Step in the Process: Hydraulic breakers are often employed in the initial stages of rock breaking. They’re excellent for breaking down large rocks or initiating fractures in bedrock.

Applications: Ideal for primary rock demolition, creating fractures, and preparing the rock for further fragmentation.

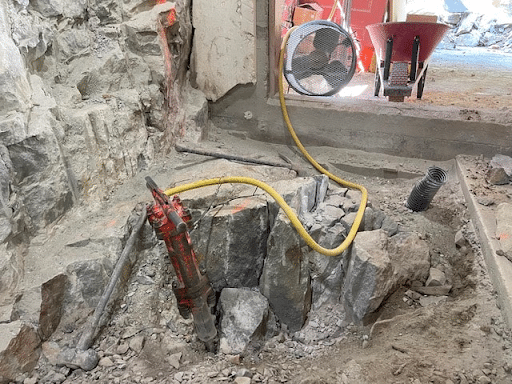

Piston Splitter:

Your mid-project best friend in the rock-breaking process.

Overview:

A piston splitter, also known as a plug and feather set or wedge set, is a manual tool consisting of metal wedges (feathers) and a central shank (plug). This tool is driven into drilled holes to create fractures in the rock.

Use in Rock Breaking:

Step in the Process: Typically used in the middle to later stages of rock breaking, after initial fractures have been made.

Applications: Effective for controlled rock splitting, especially in scenarios where precision is crucial, such as separating boulders or breaking bedrock in a controlled manner.

Expanding Grout Products:

When finesse is the key, expanding grout products like NexPro and Black Gold step in.

Overview:

They work wonders in controlled rock demolition, breaking down the toughest materials without the noise and vibrations associated with traditional methods.

Use in Rock Breaking:

Step in the Process: This is poured into drilled holes for extra rock-breaking power. A chemical process that works to break down rock.

Applications: Typically used in bedrock or large rock-breaking projects requiring no blasting where drilling is insufficient to break down the rock.

Excavators:

Your trusty sidekick. Pair them with the right attachments for precision and power. Augers and buckets for bedrock; hammers for boulders.

Overview:

An excavator is a heavy construction machine with a hydraulic arm and a bucket attached to the end. It’s a versatile piece of equipment designed for digging, trenching, and earthmoving tasks. The hydraulic system enables precise control of the arm and bucket movements, making it an indispensable tool in various construction and excavation projects.

Use in Rock Breaking:

Step in the Process: The excavator is often one of the first steps in the construction and excavation process. It plays a pivotal role in site preparation, digging foundation trenches, and clearing debris. Its ability to maneuver in tight spaces and handle various attachments makes it a crucial asset in the early stages of a project.

Applications:

- Digging and Trenching: Excavators are primarily used for digging and creating trenches, whether for foundations, utilities, or landscaping.

- Material Handling: The bucket attachment allows for efficient handling and relocation of materials such as soil, gravel, or debris.

- Demolition: Excavators equipped with specialized attachments can be used in controlled demolition, breaking down structures or removing unwanted elements.

- Grading and Leveling: The precision of the hydraulic system makes excavators effective in grading and leveling surfaces for construction projects.

- Landscaping: Excavators are employed in shaping and contouring landscapes, including creating ponds, removing obstacles, or altering terrain for aesthetic and functional purposes.

Misc Equipment:

Wheelbarrow, shovel, fan, generator, air compressor, and tarp.

Rock Breaking Safety Gear: Safety First!

Safety isn’t an option; it’s a priority. Invest in quality safety gear – helmets, gloves, eye protection – to ensure you and your team are well-protected during rock-breaking adventures.

Helmet:

Essential for head protection against falling debris and impacts.

Overview:

A proper helmet for rock-breaking jobs is a vital piece of personal protective equipment (PPE). It is designed to protect the head from falling debris, impacts, and potential hazards at the job site.

Key Features:

- Hard Shell: A durable outer shell to withstand impacts and abrasions.

- Suspension System: Inner suspension to absorb shock and provide a comfortable fit.

- Chin Strap: Ensures the helmet stays securely in place during work activities.

- Certification: Ensure the helmet meets relevant safety standards (e.g., ANSI or EN standards).

Gloves:

Protects hands from abrasions and impacts while allowing for dexterity.

Overview:

Gloves are essential for hand protection during rock-breaking jobs. The right type of gloves provides a balance of dexterity, grip, and protection against abrasions and impacts.

Key Features:

- Reinforced Palms: Protection against abrasions and sharp edges.

- Impact Padding: Extra padding on the back of the hand for impact protection.

- Secure Fit: Adjustable closures for a snug fit and to prevent debris from entering.

- Material: Choose gloves made from durable materials like leather or synthetic blends.

- Dexterity: Balance protection with the need for sufficient dexterity to handle tools.

Eye Protection:

Shields the eyes from debris, dust, and particles, ensuring clear vision and safety.

Overview:

Eye protection is critical in rock-breaking jobs where debris, dust, and particles can pose serious risks to the eyes. Safety glasses or goggles are commonly used.

Key Features:

Impact Resistance: Lenses designed to resist impacts from flying debris.

Wraparound Design: Provides side protection and ensures a secure fit.

Anti-Fog Coating: Especially important in environments where temperature variations can cause fogging.

Comfort: Opt for comfortable eyewear to encourage consistent use.

UV Protection: Ensure the lenses offer protection against harmful UV rays.

Selecting the right personal protective equipment is crucial in creating a safe working environment during rock-breaking jobs. Always adhere to safety standards and guidelines when choosing and using PPE.

Other Important ‘Tools’ for Rock-Breaking Projects

Maintenance Matters: Keep Your Tools Sharp

Regular maintenance ensures your tools and equipment are in top-notch condition. Blunt tools not only slow you down but can also compromise safety. If you want to make sure you are getting the equipment and tools right, why not utilize our Project Shipping Containers? Our Project Shipping Containers come with all the tools and equipment you need and is tailored to your rock-breaking project. So you have all the proper tools and products in tip-top-shape for every new rock-breaking job you contract! Contact us and ask about utilizing our Project Shipping Containers.

Get the Right Training: Knowledge is Power

Equip yourself with the right knowledge! Enroll in one of our training programs, attend workshops, follow our social media accounts and tune in to all our podcast episodes to stay updated on the latest rock-breaking techniques. Knowledge can be one of your greatest assets for a successful rock-breaking project! Contact us and ask about our trainings and programs.

Breaking rocks might be challenging, but with the right tools, products, and a sprinkle of know-how, you’ll be conquering bedrock and boulders like a pro. Happy breaking!

0 Comments